Armite Laboratories, Inc., operating as Armite Lubricants, is a distinguished AS9100D:2016 & ISO9001:2015 Certified establishment and a proud Woman-Owned Small Business. Renowned as a global manufacturer, designer, and wholesaler, Armite specializes in Military Spec, Commercial Spec, and Commercial Grade Chemical Compounds, including cutting-edge Anti-Seizes engineered with high-performance properties such as Corrosion Inhibition, Rust Penetration, and Lubrication. Embracing the forefront of technological advancements, Armite remains NIST SP-800-171 Compliant, ensuring robust cybersecurity standards.

Multi-Use Corrosion Preventive Compound (CPC)

Qualified by the Department of Defense and included in the QPL for MIL-PRF-81309H(1) Type 2 Class 1 (Bulk Liquid) and Type 2 Class 2 CO2 (Aerosol).

12|34® Formula’s lubricating, rust penetrating, moisture-displacing, and corrosion-preventive properties is unsurpassed by any single product of its kind.

Armite supplies the current Spec for VPP-236A(2)N3 (Technical Petrolatum) which is another great product that Armite supplies to its distributors/customers. There are two types of VVP-236, an industrial grade, and a pharmaceutical grade. The difference between the industrial and pharmaceutical grades, is typically the pharmaceutical grade is made from a lighter grade of petroleum and is yellowish in color. The industrial grade petrolatum is reddish-colored industrial petroleum jelly, it is made from a heavier grade of petroleum. This type of petroleum jelly is often used in industrial applications where high viscosity and resistance to heat, and moisture are required.

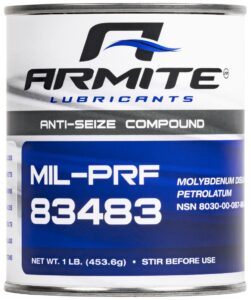

Armite’s MOLY-BLUE (MIL-PRF-83483 Revision E) is a military specification for anti-seize compounds that are used in aerospace, aviation, and other industrial and advanced manufacturing industries. This revision of the specification is specifically designed for use in aerospace applications and provides detailed performance requirements for anti-seize compounds used in this industry.

Armite’s Graphite Petrolatum Anti-Seize Compound meets SAE-AMS-2518D, formerly MIL-T-5544C. It has been utilized as an anti-seize compound for aircraft engine spark plugs, threaded fasteners, and fittings, though its applications extend beyond these uses. This compound is safe for use with austenitic corrosion-resistant steels, titanium, nickel, cobalt alloys, and other similar corrosion-resistant metals and alloys.

This zinc-based anti-seize thread compound (A-A-59313) is generally used to prevent seizing during the assembly, disassembly, and reassembly of threaded or unthreaded aluminum and aluminum alloy components. It also provides protection to metal surfaces.

Boeing Anti-Seize Compound can be used up to 350°F for threaded parts in contact with aluminum and magnesium alloys.

Armite’s Boeing Anti-Seize is used in the aerospace industry for a variety of applications, including, in general:

A Military Grade High Temp, Low Temp, and High Pressure Anti-Seize Compound

Qualified to meet MIL-PRF-907 Rev. F (Superseded by Revision H)

Armite’s proprietary MIL907 outperforms the DoD Mil-Spec MIL-PRF-907 Rev. F (which only requires a high temp of up to 1050°F (566°C). Armite’s MIL907 performs at high temperatures of up to 2987°F (1641°C) and at low temperatures of -350°F (-212°C) below freezing.

Armite’s MIL907 is an amazing Military-Grade Spec product, that can be used for commercial, industrial, and military purposes.

Quality products start with quality ingredients. Our 1001 Rust Penetrant is a hydrocarbon-based solvent used as a detergent and cleaner for painted and unpainted metal parts.

Mil-PRF-680 is an immersion & wipe solvent for removing adhesives, greases, oils, and sealants. Inherently residue-free. Very low odor. Listed on the QPL to MIL PRF 680 Type II.

Armite LP-250 is a sealing compound that prevents seizing or galling at temperatures ranging from -350°F to 2987°F (-212°C to 1641°C). This compound consists of pure lead powder suspended in a non-volatile hydrocarbon vehicle and does not dry out, even when exposed to the atmosphere. Because lead is one of the least reactive of the metallic elements, the compound is highly non-contaminative and is impervious to the effects of salt, water, steam, oils, ammonia and hydrocarbons. LP-250 is only prohibited from use with pure oxygen and Freon gases.

Armite LP-250F is a sealing compound that prevents seizing or galling at temperatures ranging from 350°F to 2987°F (-212°C to 1641°C). This compound consists of pure lead powder suspended in a non-volatile hydrocarbon vehicle that does not dry out. LP-250F is identical to LP-250, except that a pulpy filler is added to make LP-250F particularly suitable for coarse threads. This product is highly non-contaminative and is impervious to the effects of salt, water, steam, oils, ammonia, and hydrocarbons. LP-250F is only prohibited from use with pure oxygen and freon gases.

Armite’s No. 609 is a must when assembling engines, transmissions, manifolds, and other internal components. For example, when a light coat is applied to the lobes of a camshaft, the wear that occurs in the first 50 to 100 miles is essentially eliminated! Protecting these expensive parts and realizing the time saved in maintenance and repair will certainly convince anyone that Armite’s No. 609 is an essential product in the automotive and marine industries.

Armite’s ZP-770 Zinc Anti-Seize Compound

Commercial Grade

Prevents seizing and galling during assembly and disassembly of aluminum and aluminum alloy parts, engaged with components of similar or dissimilar metals.

Armite’s CP-2000 Copper Anti-Seize Compound

Commercial Grade

©2008-2025 Favia International. All rights reserved.